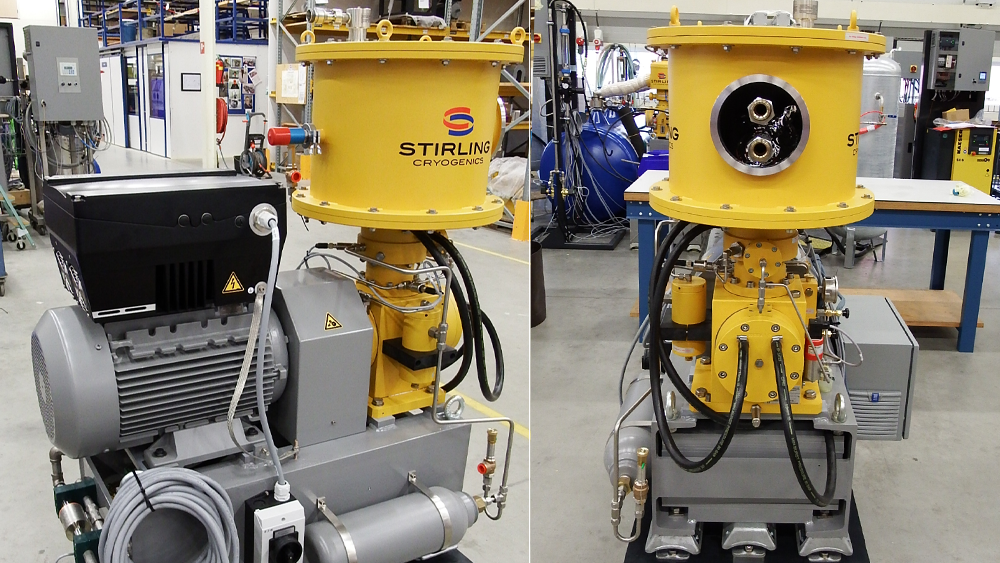

> Cryogenerators

> LNG production plants

> LNG BOG management systems

> Liquid hydrogen plants

> Liquid nitrogen production systems

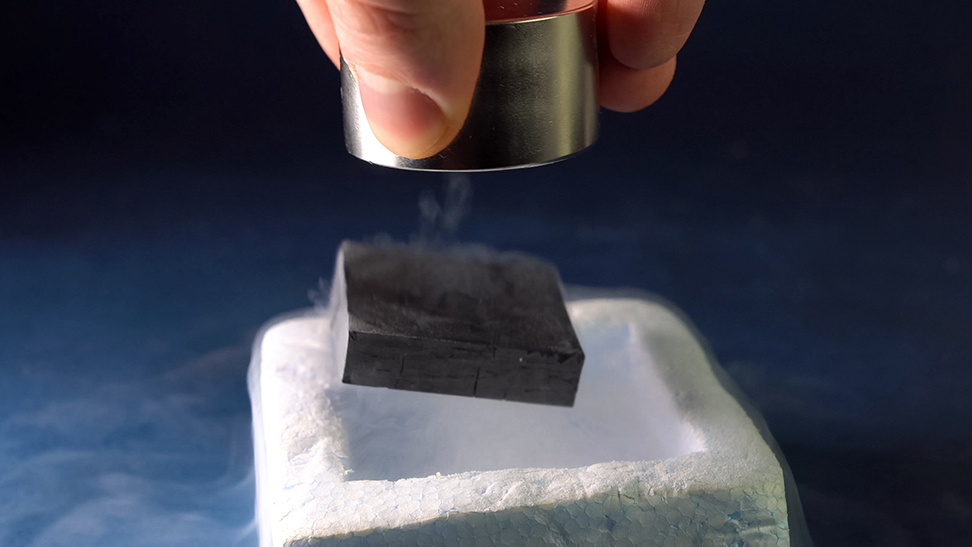

> Systems for Superconductivity

> Liquid oxygen systems

> Closed Loop Cooling Systems

> Cryogenic fans

> Cryogenic pumps

> LNG production plants

> LNG BOG management systems

> Liquid hydrogen plants

> Liquid nitrogen production systems

> Systems for Superconductivity

> Liquid oxygen systems

> Closed Loop Cooling Systems

> Cryogenic fans

> Cryogenic pumps

> LNG Production

> LNG BOG Management

> Liquid hydrogen

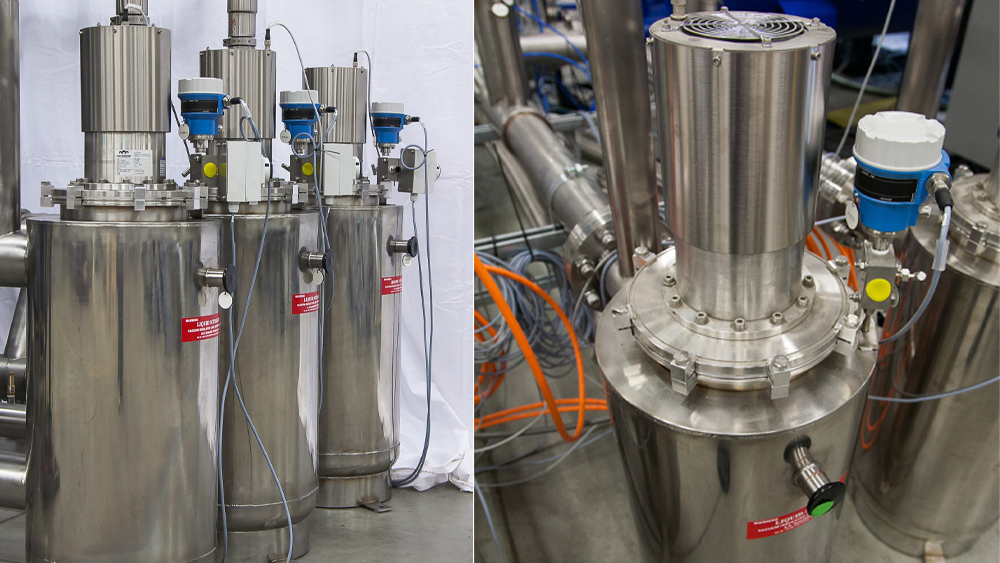

> Bio Storage

> Research & University

> Healthcare

> Superconductivity

> Food & Beverage

> Aerospace

> LNG BOG Management

> Liquid hydrogen

> Bio Storage

> Research & University

> Healthcare

> Superconductivity

> Food & Beverage

> Aerospace

> Artificial Insemination Centre, Botswana

> La Honda, Venezuela

> Bovine Al, Nicaragua

> Vet Agro Sup, France

> La Honda, Venezuela

> Bovine Al, Nicaragua

> Vet Agro Sup, France

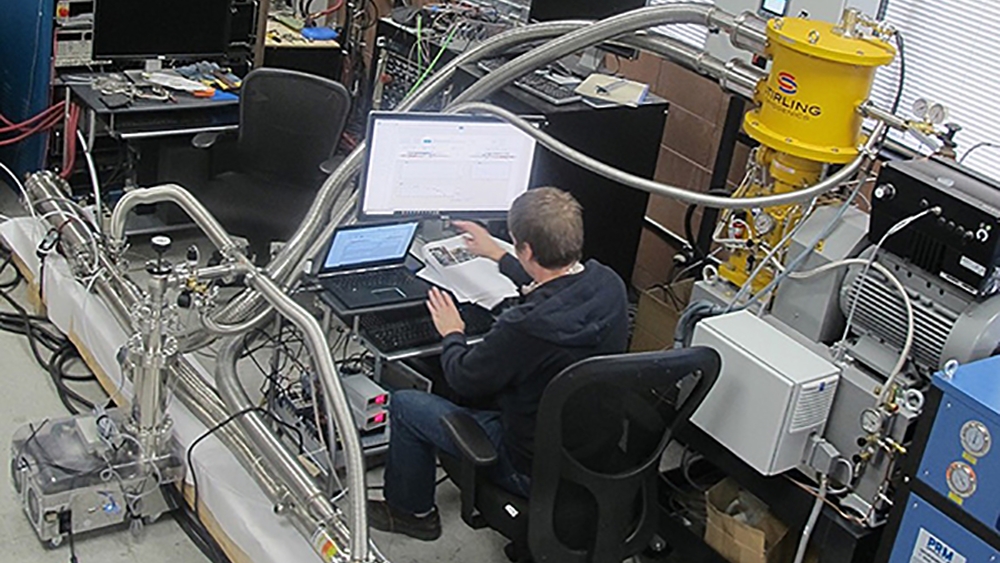

> Memorial University Newfoundland, Canada

> University of Otago, New Zealand

> CEA, Fontenay-aux-Roses France

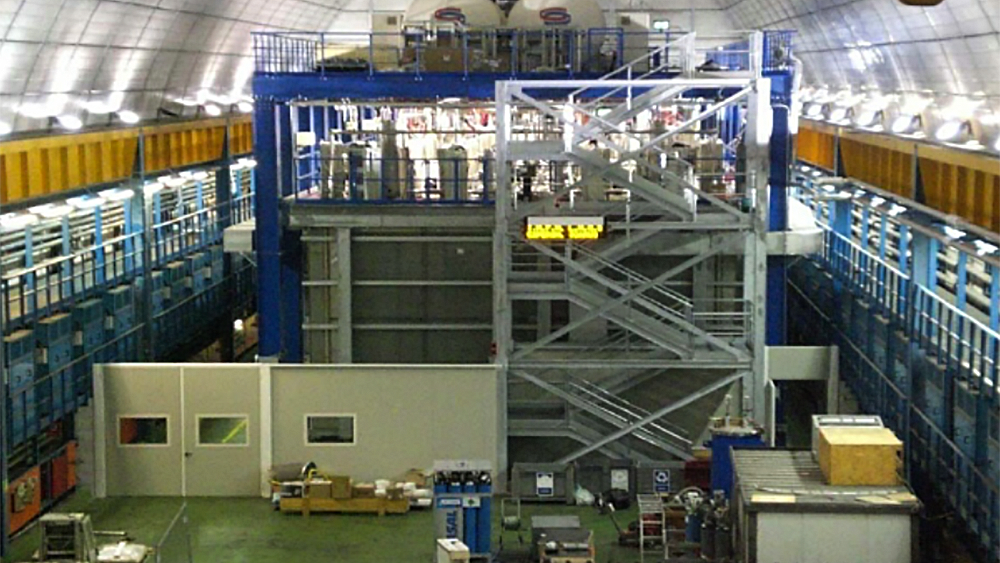

> INFN, Italy

> Snolab, Sudbury Canada

> Instituto de Ecologia, Xalapa Mexico

> IVIC, Venezuela

> Isaac Newton Group of Telescopes, La Palma Spain

> Atacama Large Millimeter Array, Chile

> Nuclear site of Chernobyl, Ukraine

> RV Sonne, Germany

> RV Maria Merian, Germany

> University of Otago, New Zealand

> CEA, Fontenay-aux-Roses France

> INFN, Italy

> Snolab, Sudbury Canada

> Instituto de Ecologia, Xalapa Mexico

> IVIC, Venezuela

> Isaac Newton Group of Telescopes, La Palma Spain

> Atacama Large Millimeter Array, Chile

> Nuclear site of Chernobyl, Ukraine

> RV Sonne, Germany

> RV Maria Merian, Germany

Head office:Stirling Cryogenics BV

Science Park Eindhoven 5003

5692 EB Son, The Netherlands

T +31 40 26 77 300

info@stirlingcryogenics.com

Offices in:USA

T +1 610 714 9801

usa-office@stirlingcryogenics.com

Germany

T +49 171 1795 994

germany-office@stirlingcryogenics.com

Sweden

T +46 766 111 728

sweden-office@stirlingcryogenics.com

Head office:Stirling Cryogenics BV

Science Park Eindhoven 5003

5692 EB Son, The Netherlands

T +31 40 26 77 300

info@stirlingcryogenics.com

Offices in:USA

T +1 610 714 9801

usa-office@stirlingcryogenics.com

Germany

T +49 171 1795 994

germany-office@stirlingcryogenics.com

Sweden

T +46 766 111 728

sweden-office@stirlingcryogenics.com

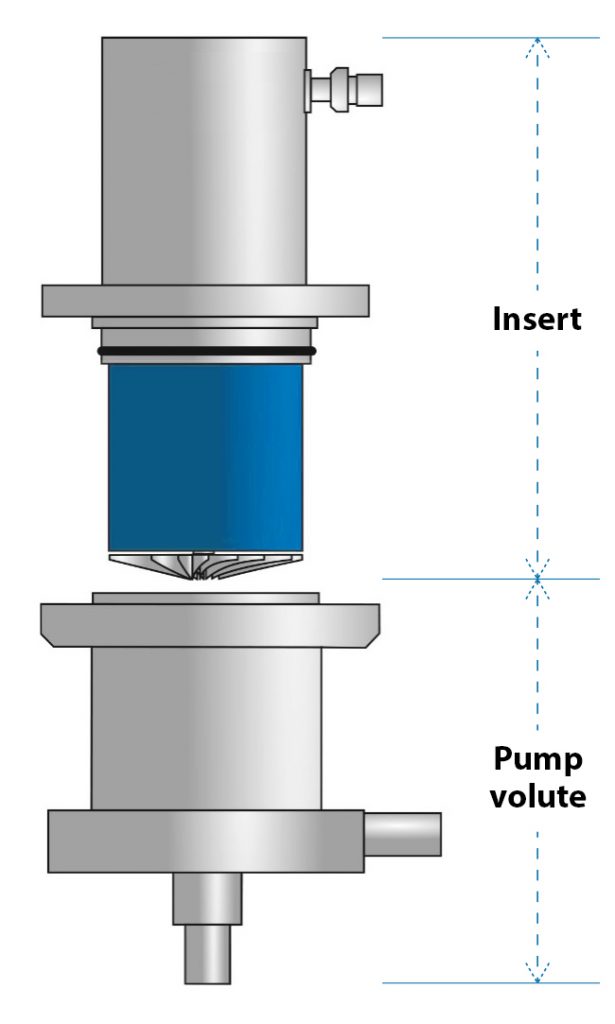

All CryoFans have the same generic design concept. Like all centrifugal pumps, the main parts are the impeller and volute. Their dimensional shape determines the functionality and efficiency of the fan.

All CryoFans have the same generic design concept. Like all centrifugal pumps, the main parts are the impeller and volute. Their dimensional shape determines the functionality and efficiency of the fan.